Some Known Questions About Motorcycle Parts New Zealand Specialists.

Table of ContentsThe Buzz on Motorcycle Parts New Zealand SpecialistsEverything about Motorcycle Parts New Zealand SpecialistsExcitement About Motorcycle Parts New Zealand SpecialistsHow Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.The Ultimate Guide To Motorcycle Parts New Zealand SpecialistsThings about Motorcycle Parts New Zealand SpecialistsSome Known Details About Motorcycle Parts New Zealand Specialists Not known Details About Motorcycle Parts New Zealand Specialists

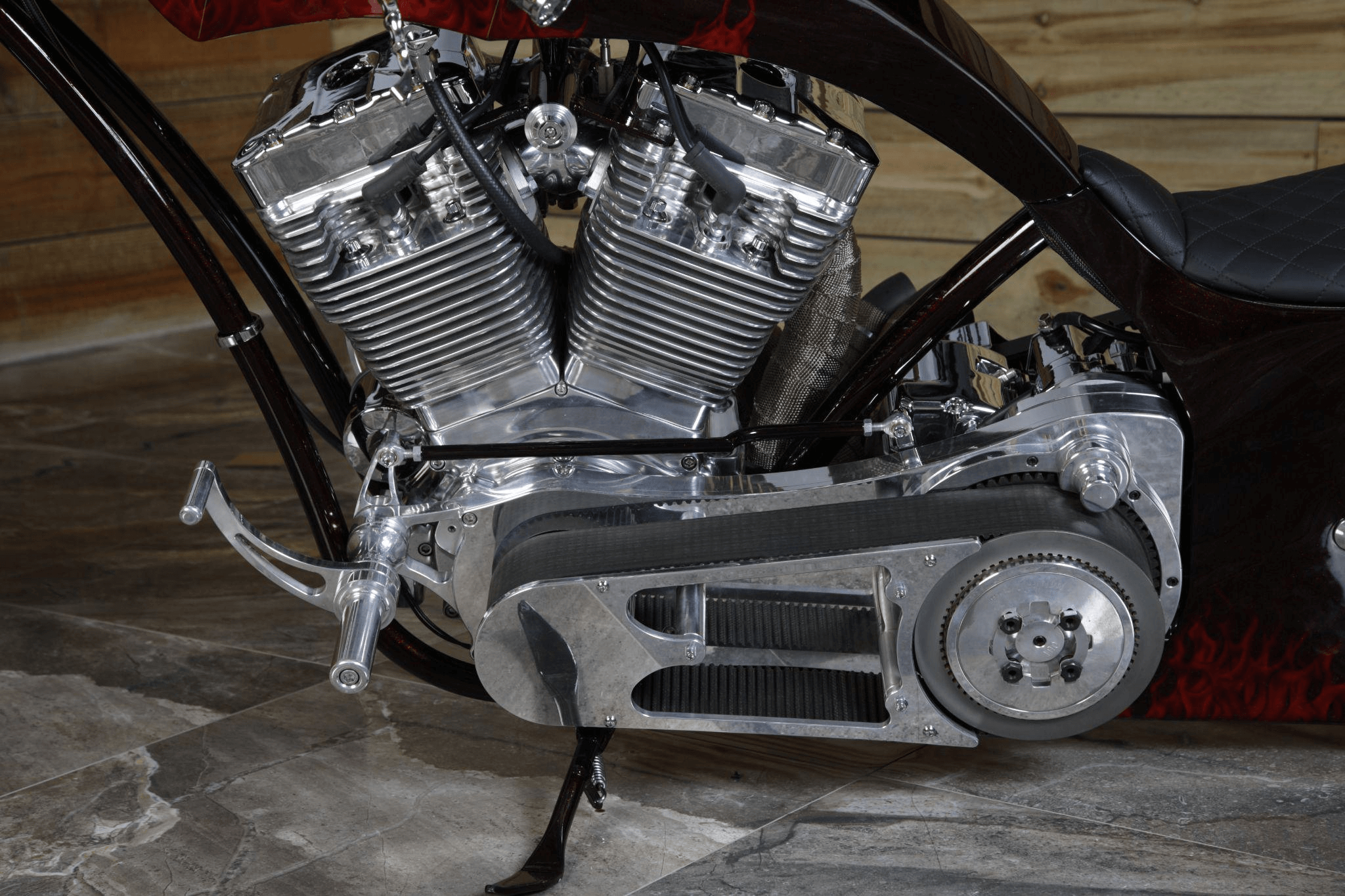

So, reach out to one of our specialists today.CNC machining technology is swiftly coming to be the focal factor of various manufacturing procedures around the world as a straight outcome of its lots of advantages over various other techniques. Furthermore, the industries that manufacture bikes have hopped on board with this trend. One of the most innovative firms are currently creating their engine components and wheels utilizing machining techniques originally created for motorcycle parts.

You may be questioning why we utilize. Now that we have your interest let us explain the reasoning behind this contemporary advancement in the motorbike production industry.

Not known Factual Statements About Motorcycle Parts New Zealand Specialists

In enhancement, you have total control over the look of the parts, even down to the minute information. Sometimes, motorcyclists may decide to spruce up their trip by installing aftermarket parts or customizing the bike's transformation.

Motorcycle Parts New Zealand Specialists Can Be Fun For Everyone

CNC machining might be made use of to make almost all of a motorbike's metal and plastic elements. To proceed, we'll review a number of machined parts for motorbikes.

When tailoring the wheels, the disks are where the emphasis ought to be. Most of them are made out of aluminum. Aluminum alloys are popular for the exceptional machining abilities that they possess. Milling procedures are used to obtain the desired level of wheel customization. Another aspect of the motorcycle that might be individualized is the tires.

What Does Motorcycle Parts New Zealand Specialists Mean?

When it concerns a vehicle (or a motorbike), one of the most vital part is the engine. Numerous individuals mention it as the "heart" of the vehicle. On the various other hand, the camshaft, the cylinder head, and the pistons often tend to be elaborate and require styles with a high level of accuracy.

Use only high-quality things, however, because these lights are critical for the safety of motorcyclists and various other drivers or people on the road, particularly at night. Bike fronts lights have 3 main parts: the light bulb, or light source, the lens, and the real estate.

Milling processes with a flawless coating would cause the lenses having a reflective click this link top quality that is comparable to that of a mirror. The cover, on the other hand, is not composed of breakable products; instead, it is built out of challenging polymers that can be machined right into more intricate patterns.

The Motorcycle Parts New Zealand Specialists PDFs

Motorbike manufacturers commonly cast these components, yet only for the production of bespoke parts. Machining on 5 axes in today's world is the methods by which any layout form may be recognized.

The success of the procedure is contingent on the mill cutters' capacity to compute refined and complex angles precisely. Pick Runsom for your customized motorbike components! We have the capacity to produce difficult and elegant parts making your bike incomparable. A lot of are crafted from light weight aluminum or steel alloys, each of which has its usages and advantages.

Below are a couple of examples of metals typically utilized in motorcycle component machining. Light weight aluminum is the main material made use of by firms specializing in creating personalized motorbike elements to create many of these parts - Motorcycle Parts New Zealand Specialists.

Zinc describes an additional metal additional hints that is really light in weight and has wonderful machining top qualities because of its high mechanical strength. This product may be formed right into nearly any form and preserves its dimensions well. Even mission-critical parts that need a high level of precision may take advantage of their use.

The Best Guide To Motorcycle Parts New Zealand Specialists

An additional metal that sees heavy usage in the production of CNC-customized components is magnesium. It is amongst the lightest steels that are currently obtainable and has excellent machinability features and stamina commensurate with its reduced weight. Among the drawbacks of magnesium is that its dust may conveniently ignite.

Their most typical use in producing various bike elements is fasteners, such as screws and screws. Their low susceptibility to oxidation and deterioration makes them optimal for this use.

Our Motorcycle Parts New Zealand Specialists PDFs

It appears that CNC transforming and crushing are the fundamental procedures. In enhancement, it calls for maintaining bars of material, most commonly plastic or steel, in setting and then twisting a cutting tool to get rid of areas of the product as the product is transformed.

These methods are similarly important and produce parts with high accuracy and constant quality. The processes aid enhance the total quality of the machined motorbike parts.

Getting My Motorcycle Parts New Zealand Specialists To Work